Case 4: Efficiency Expansion"Whether you think you can or think you can't - you're right." ~ Henry Ford |

|

|

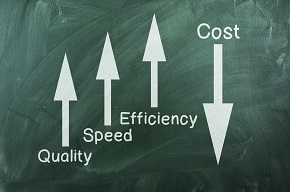

| Situation | When production was constrained, two businesses believed that adding “bricks and mortar” was necessary to satisfy demand. Working with both management teams, consultant conducted a detailed factory-floor assessment that uncovered hidden “capacity”. | |

| Background |

- Semi-custom product |

- Major piece of capital equipment |

|

Analysis & Action: Our Process |

- Reviewed: material flow, key equipment, floor layout, factory standards and storage

techniques - Shortened assembly line 25% by grouping production steps - Established visual standards for tracking production |

- Staged work for visual job tracking and timed each step of the production process - Expanded review to material planning, sequence of fabrication, and assembly line layout - Streamlined production to an 8-hour “moving” line assembly process |

| Result |

- Nearly doubled facility output over five years - Reduced year-over-year labor cost by 50% |

- Lowered labor costs by almost 40% without the need for expensive capital investment - Applied lessons learned to other product families |